Test Services & Automated Solutions for Data Center Infrastructure Planning

Make every component click like a puzzle piece.

The rising demand for greater data center capacity

Rising demand for capacity and scale

Data centers of the future must accommodate surging demand for data storage and processing capacities. With the rise of 5G technology, IoT networks, and AI, modern data centers grapple with greater scale demands while still keeping space and cost expenditure low. For business incumbents with existing legacy infrastructure, backwards-compatible data center components can help meet demand while eliminating the need to build new centers from scratch.

Flexibility to weather future uncertainty

Newer enterprises will also have to plan carefully to hedge data center expenditure against economic fluctuations so that both their business models and next-gen data centers remain viable in the long run. Our established partnerships, which includes more than 10 years of working with Intel, gives our customers reliable access to the latest standards in electrical validation, functional validation, cable compliance, and other essential components in data center testing.

Revised data center validation standards

Market Access Services

Everything you need to know to swiftly usher your data center components into new markets.

Tap into our rich network of data center test experts

- Motherboards

- Network to network

- SSD

- Storage

- PCIe

- PC server system boards

- Product for Ethernet

- Electrical compliance automotives: Interconnecting interfaces between ICs and devices to host

An overview of data center specifications

What is High Performance computing (HPC) and High Bandwidth Memory (HBM)?

How do chiplets form the Universal Chiplet Interconnect Express (UCIe)?

Chiplets, as the name suggests, are tinier than your average computer chip. They were first designed in response to the industrial shift towards smaller process nodes. As tiny integrated circuits designed for specific functions, chiplets act as building blocks for Universal Chiplet Interconnect Express (UCIe). In turn, UCIe refers to the collective network of connections between chiplets that form an open ecosystem at the package level.

Chiplet-based designs act as an intermediary to help data centers transition away from older nodes (16-28nm) to lower nanometer designs while still tapping into them for certain functions in legacy systems. The nature of UCIe allows for ecosystems to be customized according to various business needs, creating networks that combine functions from various notes, and even opportunities for cost reductions if specialized chips are produced at scale.

What is the RISC-V (Reduced Instruction Set Computer) ecosystem?

The RISC in RISC-V stands for Reduced Instruction Set Computer, a set of specification instructions that are used to build hardware and software that form the wider RISC-V ecosystem. The RISC-V in turn is an open specification and platform that consists of components that spread across low-level firmware, boot loaders, system kernels, applications, as well as design and verification tools.

As an open specification built on unique design principles, RISC-V forms the foundation of many commercially available software and hardware, creating a common software toolchain where efficient pipelines of optimized operations can be built. As data centers continue to grow, RISC-V optimization will become increasingly crucial in meeting ever-increasing consumption levels while drawing greater outputs sustainably through higher performance per watt.

Do data centers need to be certified?

Automated test solutions for data center infrastructure planning

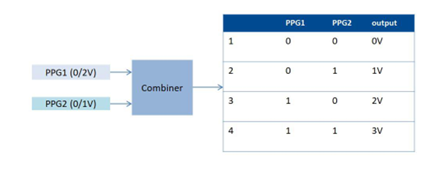

Bit Error Ratio Tester (BERT)

Probably the most critical instrument when it comes to stressed receiver calibration, only BERT that exhibit desirable traits of fast rise time and low intrinsic noise qualify.

Electrical-to-Optical (E/O) converters

E/O converters must have automatic bias control, an input linear amplifier, and a Mach-Zehnder modulator to convert electrical signals generated from BERT into optical signals that can be applied to receivers-under-test.

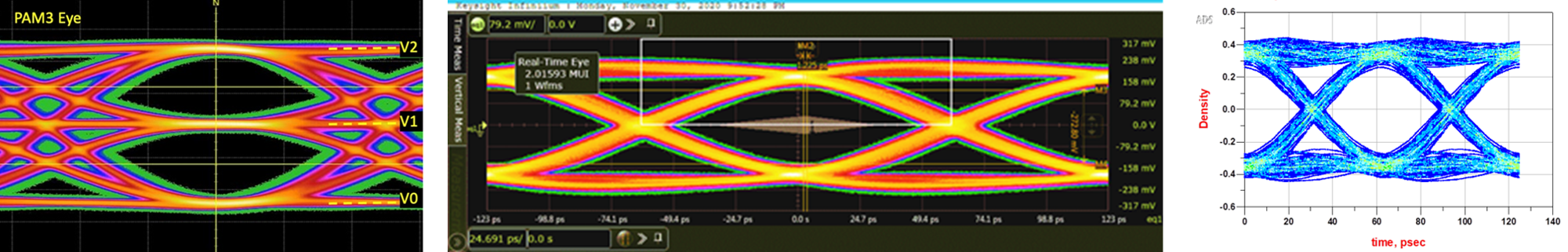

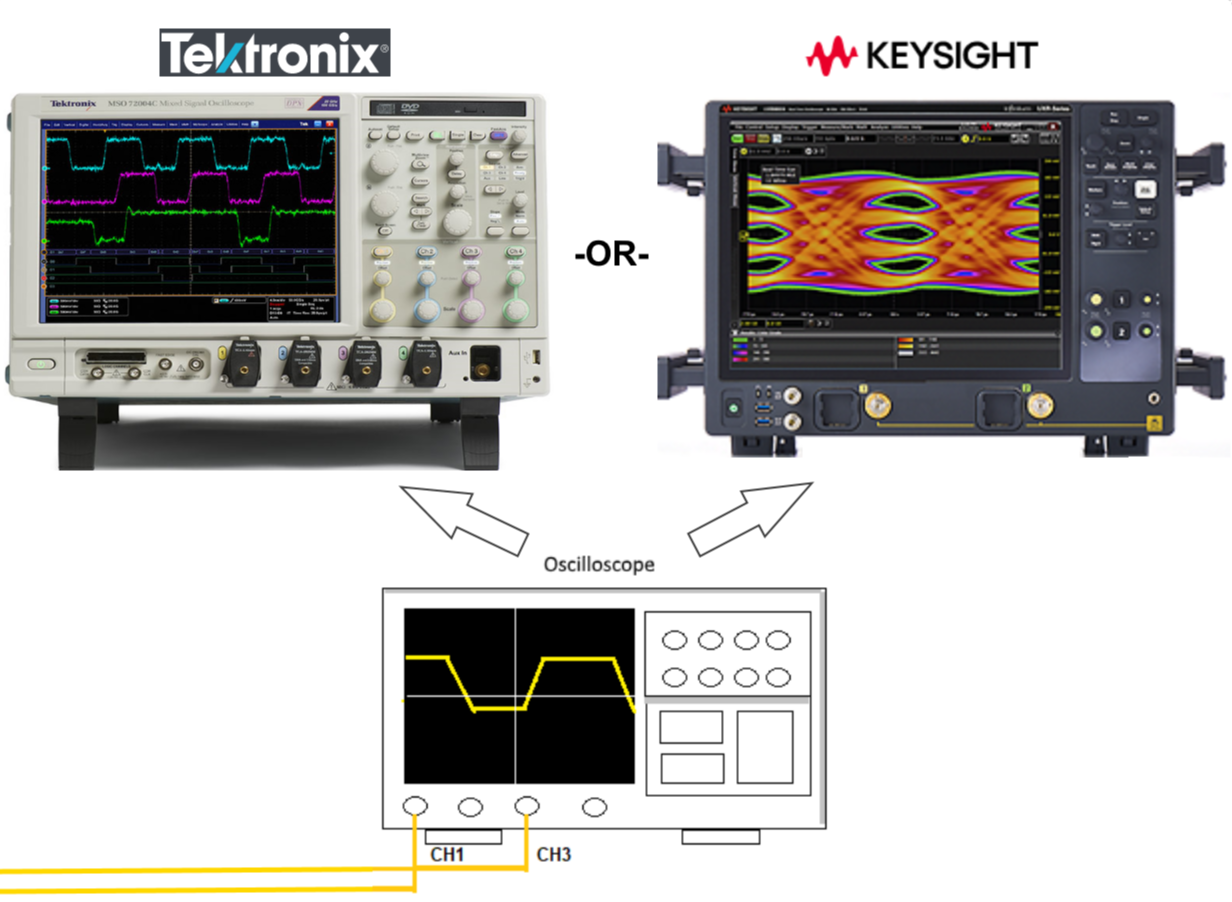

Oscilloscopes

Only high-bandwidth sampling or real-time oscilloscopes are selected after taking into account factors such as combined noise floor of the scope and optical front-end as well as intrinsic scope and optical front-end noise.

Browse our data center solutions!

Browse features of the PCI Express® PLL Test Automation Solution and GRL PCI Express® Transmitter Test Automation Solution, both complete with scopes from Tektronix and Keysight.

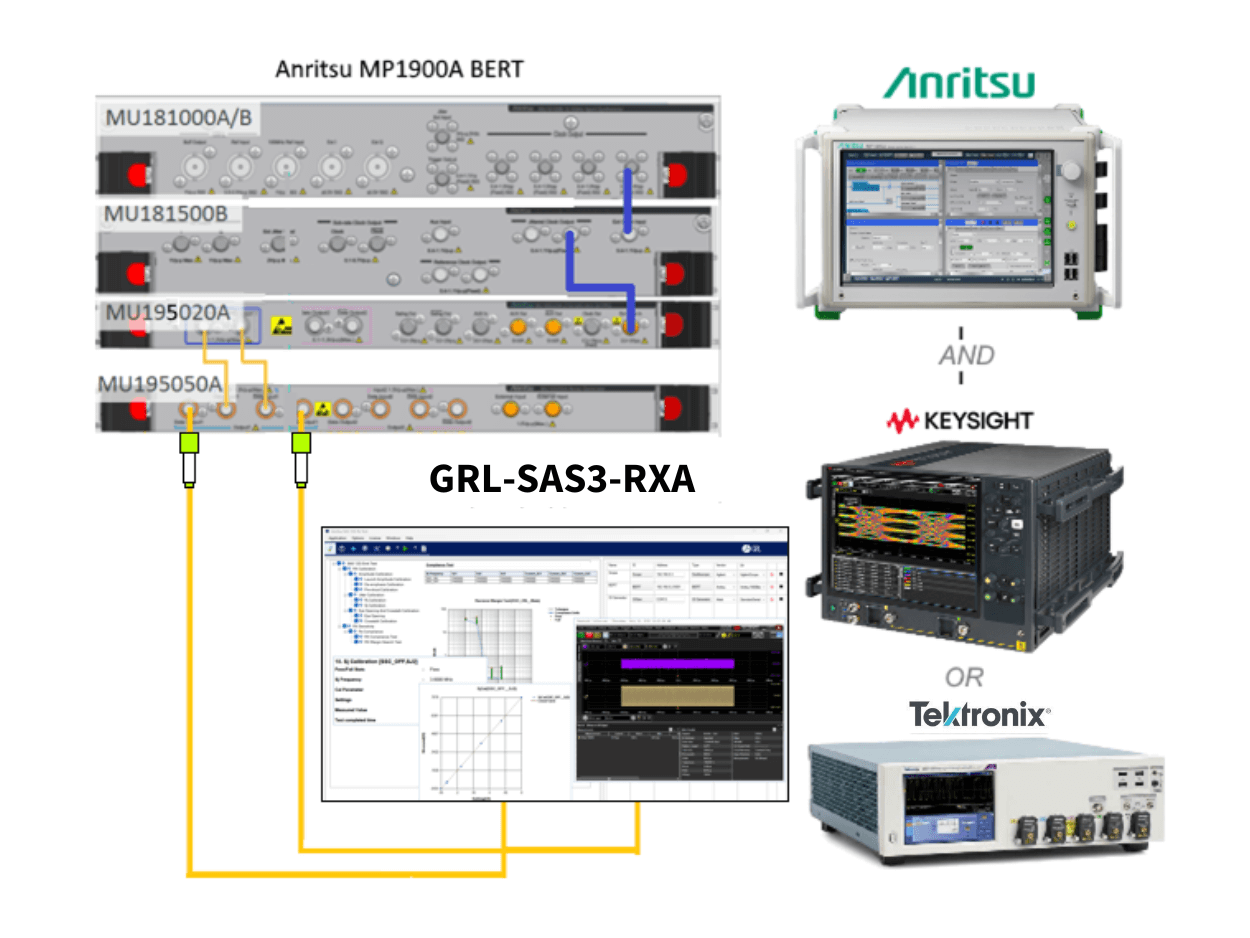

Also available are the SAS-4, SAS-3, and USB4® automation software for Anritsu MP1900A BERT receiver test and Tektronix receiver calibration.

Only the latest news

Always stay at the forefront of cutting-edge technology when you subscribe to the GRL newsletter.

-1.png?width=200&height=150&name=USB4-RXA%20(1)-1.png)

/HDMI%20eARC%20%E8%81%B2%E9%9F%B3%E5%9B%9E%E5%82%B3%E5%8A%9F%E8%83%BD%E6%A6%82%E8%BF%B0.png?width=693&height=462&name=HDMI%20eARC%20%E8%81%B2%E9%9F%B3%E5%9B%9E%E5%82%B3%E5%8A%9F%E8%83%BD%E6%A6%82%E8%BF%B0.png)

/HDCP%201.x%20Overview_featured%20image.jpeg?width=882&height=588&name=HDCP%201.x%20Overview_featured%20image.jpeg)

/HDCP%202.x%20Overview_featured%20image.jpeg?width=1800&height=1200&name=HDCP%202.x%20Overview_featured%20image.jpeg)